Industry

Increasingly tough competition for the Swedish manufacturing industry increases the need for constant efficiency improvements in a number of areas. To succeed, this requires access to solid expertise that even larger organizations have difficulty mastering on their own.

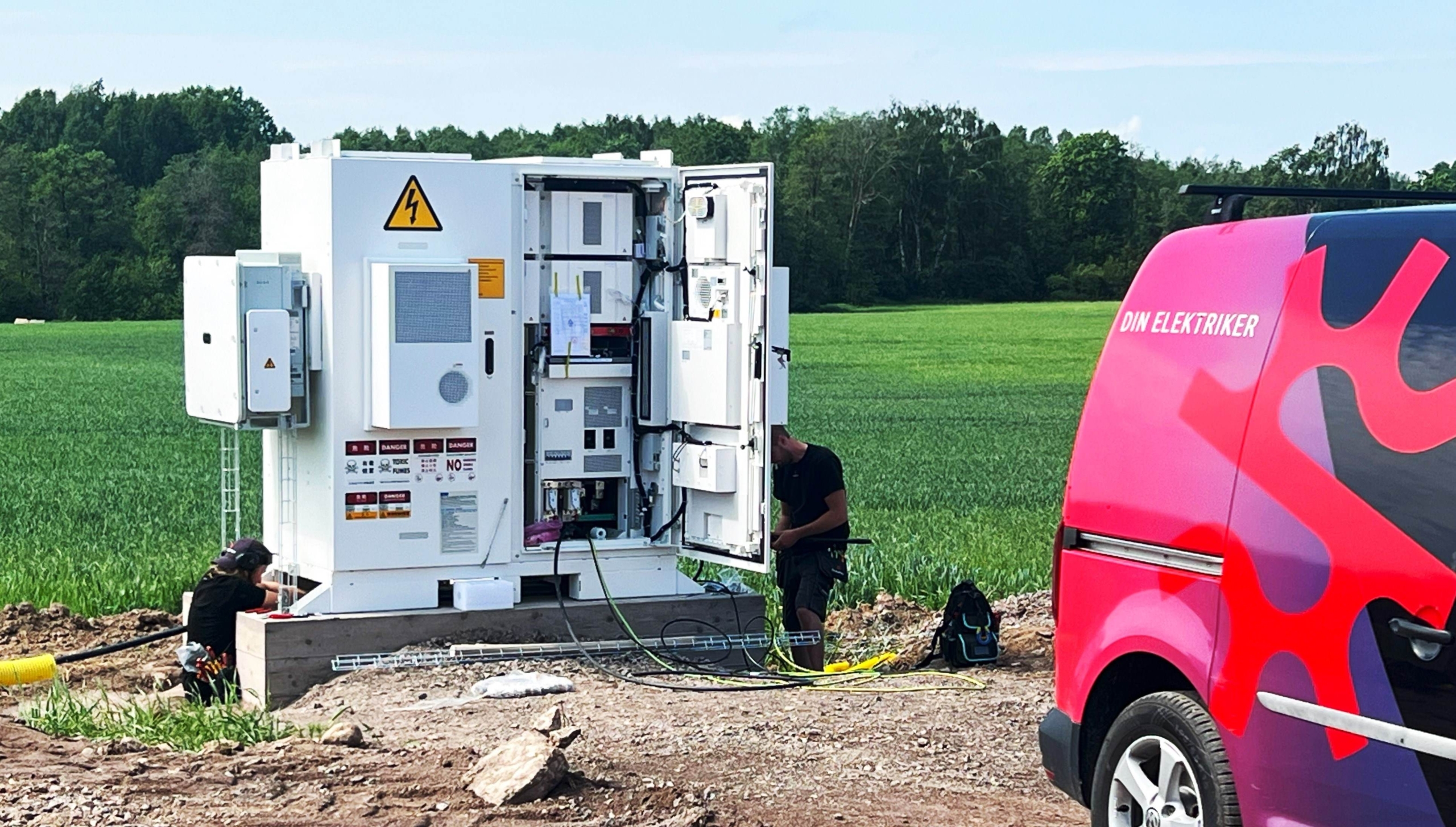

Total solutions in electricity, automation and security

This may involve, for example, increasingly advanced electrical installations, automation solutions or energy efficiency - all things that we at Provektor solve for our customers on a daily basis. Security issues are also rapidly becoming more important - in today's social climate, it is important to protect your business against accidents, sabotage and theft. Here we have well thought-out solutions for locks, alarms, camera surveillance and passageways that provide full control over who has access to the property.

Flexible identification systems not only prevent unauthorized access, but also make life easier for your authorized staff, as electronic, computer-controlled systems can greatly replace physical keys. Cameras can also be used for product identification, which in turn controls, for example, logistics flows on conveyor belts and so on.

Future-proof solutions for your industry

Despite ambitious efficiency efforts, the need for electricity continues to increase for most industrial companies, not least in connection with the transition to an electrified vehicle fleet. Here we have the latest technology and the right know-how to develop optimized solar energy solutions on roofs, facades or ground. Generally rising electricity prices, concerns about grid capacity, and the decreasing share of balancing power in the electricity mix make self-generation a better investment than ever.

Complemented by battery storage and phase balancing, we can minimize your company's costs, while helping to keep the Swedish grid healthy. Of course, we also have well-proven solutions for charging electric cars as well as trucks and self-propelled transport trailers.

References

-

Brighter and smarter - upgrading the lighting at CWS Workwear

→: Brighter and smarter - upgrading the lighting at CWS WorkwearReplacement of fluorescent luminaires. A step to reduce environmental impact and make a big energy saving. It also provides a much more pleasant and functional light in the premises.

-

-

Curious about Provektor? Get in touch and we'll tell you more!