Wastewater treatment plant in Älmhult

Skara - Älmhult 2002-2017

The municipality of Älmhult set an environmental target at the beginning of 2001 to improve sludge treatment at the municipality's wastewater treatment plant and to reduce the deposition of treated sludge and organic household waste at Äskya waste facility. As a result, the wastewater treatment plant was expanded with a biogas plant and reed beds. In connection with the expansion, a total renovation and completion of the wastewater treatment plant was carried out. Among other things, the biological treatment stage was modified for biological phosphorus reduction, which has reduced the use of precipitation chemicals.

Mission

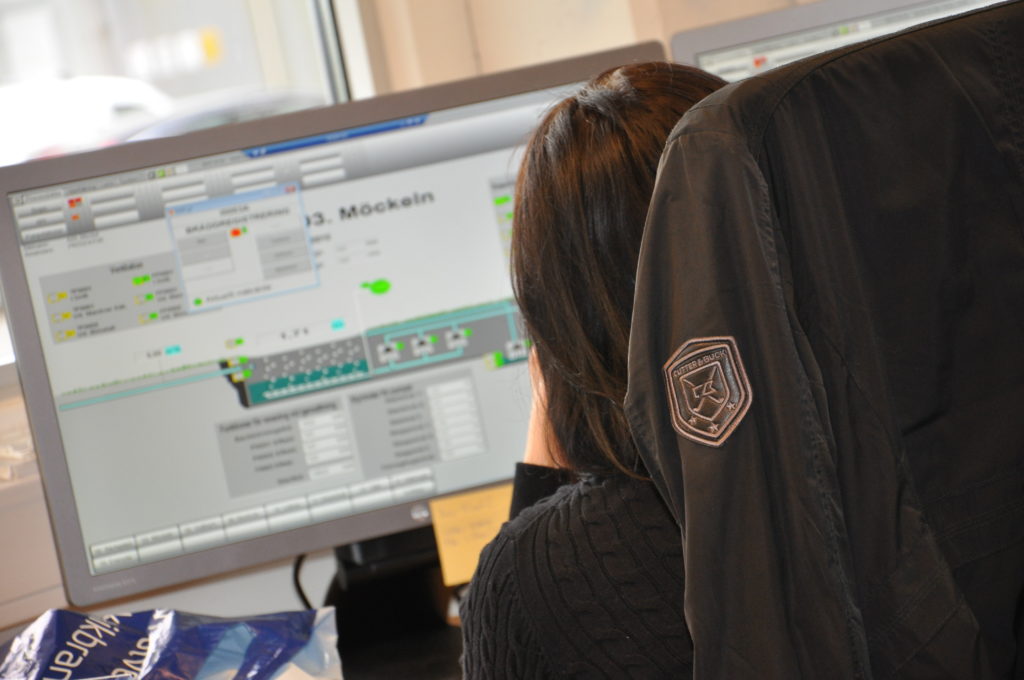

As UE to Läckeby Water, Provektor carried out electrical installation and control automation with programming and commissioning of the biogas plant, which was the first stage. The next step was to also replace the electricity and controls in the rest of the treatment plant. This also included programming and commissioning of PLC and Scada systems. ABB control systems and ABB sattgarap500 help the operator to have full control of the plant. Integration of a number of control systems that interact through bus systems gives the plant a flexibility and almost infinite access possibilities. Among other things, frequency controlled motors and improved instrumentation help the operator to control the plant and thus reduce energy consumption and improve emissions.

Provektor has delivered controls to a number of pumping stations that are controlled and monitored via fiber or GSM communication. The contact with the control systems in each of the stations makes the pumping station less vulnerable but also enables the operator to control and monitor remotely. Over the years, Provektor has developed a complete solution for pumping stations and booster stations consisting of a PLC with associated operator panel. External communication with the station is done with fiber technology or GSM modem.

2002-2004 Älmhult municipality carried out a major renovation of the sewage plant, a new digestion plant was built to be able to grind down household waste together with extracted sludge and then extract methane gas. The residual digested sludge passed through the treatment plant and was finally flushed onto reed beds before final treatment. It is then released into the environment for a new cycle.

The contract included control systems and Scada systems from ABB. Batch handling to heat the substrate before homogenization then into the digester for extraction of methane gas. The process programming was performed in ABB 250 system and the scada system was programmed in NT structure which was then the latest operating system for servers. Network with aspect server and history server to store data for a five year period to control the level of purified water and any contaminants analyzed.

2009-2011 a number of pumping stations so called transmission line was refurbished and replaced with new control automation with commissioning and programming of Provektor.

2014 all CPUs of type ABB Satcon 200 were changed to ABB AC800M. The old Sattbus communication was replaced by extended MMS communication. Modem communication was removed and replaced by TcpIp communication.

2015 The incoming station for the treatment plant in Älmhult began to fall for the age limit. Components have started to be phased out and spare parts for the electronics are becoming too old and unreliable. Replacement of the control system where previous io cards were checked and then reused. The existing PLC program was converted to a new ABB standard, tested in simulated mode and then commissioned on site for one day. The commissioning problem is that the process cannot stop as the sewage inflow causes the water to rise and risks flooding the basement. The commissioning was carried out according to plan without any disturbances.

In 2017 it was time to replace the existing scad system in Älmhult. The choice ended up on Ifix. The existing database from Sattgraph was restructured and the old comli communication with plc was replaced with OPC server. With the change of scada, Älmhult is given the opportunity to grow and integrate additional stations via the municipal network. It is also possible to interconnect waterworks that have a higher level of security via redundancy on the municipality's fiber network. This places great demands on IT security.

Curious about Provektor? Get in touch and we'll tell you more!